Introduction to Chassis Coating for Shipping Containers

When it comes to prolonging the life of a shipping container, chassis coating is a key player. Think of it as the container’s armor against corrosion, wear, and tear from constant movement and harsh weather conditions. This process involves applying a protective layer over the chassis, the frame that supports and transports the shipping container. The right coating shields the metal against moisture, salt, and other elements that can lead to rust and damage. Various types of coatings are available, each with its own set of benefits. Some are designed for extreme durability, while others focus on environmental friendliness. The bottom line is that investing in a good chassis coating can save you a lot in terms of maintenance and replacement costs. It’s not just about keeping the container in good shape; it’s about ensuring that whatever you’re transporting remains secure throughout its journey.

Understanding the Importance of Chassis Coating

Chassis coating is essential for keeping your shipping container’s frame safe. Think of it as armor. Without this coating, the chassis risks rust and wear. A good coating can drastically increase your container’s lifespan by fighting off the elements. Whether it’s enduring damp docks or braving ocean voyages, this layer keeps your container robust. Economically, it’s a wise choice too. By investing in quality chassis coating, you cut down on future repair and replacement costs. It’s all about saving cash and sparing yourself unnecessary trouble. So, when eyeing your shipping container’s well-being, don’t skip out on getting a strong chassis coating. It’s a simple move that greatly benefits your container’s endurance and strength.

Types of Chassis Coating Available

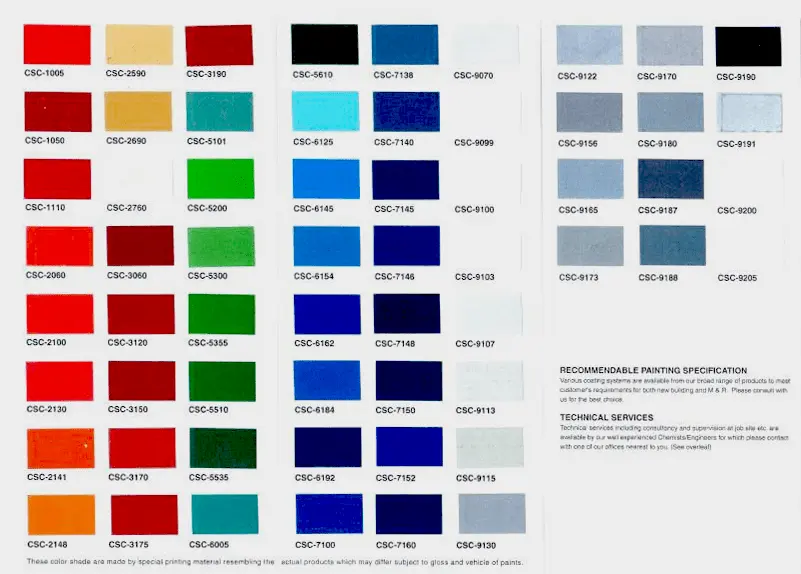

When you’re looking into chassis coating for shipping containers, you’ve got a few choices to consider. Each type has its own pros and cons, depending on what you’re looking for. Let’s break it down. Zinc is a popular choice for its corrosion resistance. It fights off rust like a champion, making it a solid pick for containers braving the high seas. Epoxy coatings are all about durability. They bond to the chassis with a vengeance, providing a tough layer resistant to impact and abrasion. Ideal if your container’s going to be roughing it out on long journeys. Polyurethane brings flexibility to the table. It’s resilient against UV light and extreme temperatures, keeping your container in top shape under the sun or in the cold. Powder coatings are the eco-friendly warriors. They’re applied dry, minimizing waste and avoiding harmful solvents. Plus, they come in various colors, allowing for some customization. These options serve different needs, from battling rust to enduring rough conditions or reducing environmental impact. Choose based on what challenges your container will face.

The Benefits of Applying Chassis Coating

Adding a chassis coating to shipping containers is a wise move, not just an extra step. It’s tough defense in action. It battles rust, corrosion, and the damage from weather and travel. Each journey on the road or time at the docks means a fight against the elements. Rain, snow, salt, and even the sun’s harsh rays can weaken it gradually. A sturdy chassis coating acts like giving your container a suit of armor. It’s not just for looks; it’s for longevity. Though it might look like an extra cost at first, it’s an investment that pays off. Your container remains robust, cutting down future costs on replacements or fixes. Plus, a coated chassis can bear heavier burdens and endure more challenging journeys. Whether it’s traversing deserts or climbing mountains, that layer of protection keeps it in top condition, ensuring safe delivery of your goods. In essence, view chassis coating as a shield. It offers protection, extends lifespan, and prepares your shipping container for all that’s to come, marking it as a smart, essential step in upkeep.

Preparing Your Shipping Container for Chassis Coating

Before you even think about chassis coating, you need to prep your shipping container properly. This isn’t just a quick wipe-down; it’s about making sure the surface is ready to bond with the coating. First off, you need to clean the container. Get rid of any dirt, grease, or rust. A power washer can do wonders here, but for tough rust, you might need a wire brush or sandblasting. Just make sure the surface is smooth and clean. Next, repair any damage. Dents and holes can hinder the coating process, so they’ll need to be corrected first. You can use body filler for small dents and patch up holes as needed. Lastly, apply a primer. This step is key. It gives something for the chassis coating to grip onto, making sure it sticks around for the long haul. Once you have done all this, your shipping container is ready for chassis coating. This prep work is going to make sure your chassis coating does its job, protecting your container from rust and corrosion.

Step-by-Step Guide to Applying Chassis Coating

First, you’ll want to gather your materials. You’re looking at needing a high-quality chassis coating paint, a wire brush, sandpaper, and perhaps a primer if the metal is very rough or rusted. Gloves and safety glasses are a must too; don’t skimp on safety.

Next, clean the chassis. Use the wire brush to get rid of any loose rust and old paint. Then, go over it with sandpaper for a smoother finish. It’s about getting the surface as ready as possible so the coating sticks well.

If you’re dealing with heavy rust, applying a primer is your next step. It’ll help the coating adhere better and provide an extra layer of protection. Make sure the primer is specifically designed for use on metal surfaces.

Now, the main event: applying the chassis coating. Stir your paint well, then use a paintbrush or spray gun to apply it evenly across the chassis. Work in thin layers to avoid drips and ensure an even coat. You might need several layers, so patience is key here.

Lastly, let it dry as advised by the paint manufacturer. Rushing this part can ruin your hard work, so give it ample time. Once dry, you’ll have a chassis that’s protected against rust and corrosion, extending the life of your shipping container.

Remember, doing this right means doing it once rather than having to patch up or completely redo your work in a few years.

Maintenance Tips for Coated Chassis

Keeping your chassis coated and in top condition doesn’t just happen by chance. It demands regular attention. First off, inspect your chassis regularly for any signs of damage or wear. This isn’t just about looking good; it’s about preventing rust and corrosion, which can seriously shorten your chassis’s life. When you spot issues, act fast. Small problems can turn big if ignored. Clean your chassis often. Dirt, grime, and salt from roads can stick to your coating, eating away at it over time. Use mild soap and water, and give it a thorough rinse. Touch up any scratches or chips in the coating as soon as you see them. Ignoring them is like sending an open invitation to rust. If your chassis has been through a lot or the coating looks worn out, consider reapplying a coat. This can dramatically extend its service life. Finally, make sure to use the right products. Not all coating materials are created equal. Go for quality, even if it costs a bit more. It’s an investment in your chassis’s longevity. Stick with these simple tips, and your coated chassis will serve you well for years to come.

Common Issues with Chassis Coating and Solutions

Chassis coating might not seem like a big deal until you face rust and corrosion. These are the main enemies of any shipping container chassis. With exposure to different weather conditions and constant wear and tear on the road, it’s not a question of if but when these issues will show up. Rust starts small, but it can quickly spread, weakening the structure of the chassis. Corrosion, on the other hand, eats away at the metal, causing serious damage over time.

But here’s how you can tackle these issues head-on. First off, regular inspections are key. Catching rust early means you can deal with it before it becomes a bigger problem. For minor rust, a simple sanding and touch-up with a rust-inhibiting primer might do the trick. When corrosion kicks in, however, you might need to strip the area, apply a rust converter, and then recoat it with a high-quality chassis paint designed to withstand the elements.

Consider applying a protective coating before these problems even start. Look for coatings that offer UV protection and are resistant to chemicals and abrasions. Some products are designed specifically for shipping container chassis, creating a barrier against moisture and salt – two big causes of corrosion.

In summary, stay vigilant with inspections, act fast at the first sign of rust, and invest in a high-quality protective coating. Your shipping container chassis will thank you for it by lasting longer and performing better.

Comparing Chassis Coating Costs and Options

When it comes to protecting your shipping container, choosing the right chassis coating is crucial. But with several options out there, it’s easy to get tangled in details. Let’s simplify it. Essentially, you’re looking at two paths: cheaper, basic coatings or pricier, more durable solutions. On the budget-friendly side, you’ve got alkyd-based paints. Stepping up, epoxy coatings offer a tougher shell. They’re resistant to corrosion, chemicals, and wear but can be more expensive per gallon. It’s a smart move if your container faces mean conditions or you’re keen on long-term savings. For those in marine environments or demanding the ultimate protection, polyurea coatings are the top-tier choice. They’re practically invincible against weather, chemicals, and abrasion. This premium option can cost $500 or more per gallon, but it’s like armoring your container for a marathon across decades. Bottom line: You get what you pay for and investing in durability pays off. Consider your container’s mission, the beating it’ll take, and how often you’d like to revisit the coating conversation.

Not sure which type? Contact the experts at Delta Mark can help you choose the right option for your needs.

Conclusion: Extending the Life of Your Shipping Container with Chassis Coating

Wrapping it up, chassis coating isn’t just another expense; it’s a smart investment to protect your shipping container from rust and corrosion, ensuring it stands up against time and the elements. Think of it like this: you’re not just spending money; you’re buying longevity and reliability for your container. The cost might vary based on the coating material and the professional you choose for the job, but remember, the right chassis coating can significantly extend your container’s life. So, weigh your options, but don’t skimp on quality. A well-protected container serves you longer, saving money and hassle in the long run.