At Delta Mark, we understand the critical role container chassis parts play in the transportation industry.

This comprehensive guide will explore the essential components that make up a container chassis, from frame elements to electrical systems.

We’ll delve into maintenance best practices, help you choose the right parts, and discuss the importance of quality components for safety and efficiency.

Whether you’re a seasoned professional or new to the field, understanding container chassis parts names and their functions is key to optimizing your operations.

What Are the Key Container Chassis Parts?

Container chassis form the backbone of intermodal transportation. Understanding their components is essential for efficient operations. Let’s explore the critical parts that make up a container chassis.

Frame Components: The Chassis Foundation

The frame provides the structural foundation of any container chassis. It typically includes:

- I-beams

- Cross members

- Goosenecks

These elements work together to support the container and maintain structural integrity.

Suspension Systems: Smooth Transport

Suspension systems absorb shocks and maintain stability during transport. Most container chassis use:

- Air ride suspensions

- Spring ride suspensions

Air ride systems offer superior protection for sensitive cargo.

Brake Systems: Safety at the Forefront

Brake systems are vital for safety. Modern chassis often feature:

- Anti-lock braking systems (ABS)

- Automatic slack adjusters

Electrical Components: Powering Safety Features

Electrical systems on container chassis include:

- Lighting

- ABS controls

- GPS tracking (in some models)

LED lights have become the industry standard. They offer up to 50,000 hours of operation (compared to 5,000 hours for traditional bulbs). This longevity translates to significant savings in maintenance costs over time.

Tires and Wheels: Critical Contact Points

Tires and wheels play a crucial role in safety and efficiency. Consider these facts:

- Low rolling resistance tires can improve fuel efficiency

- High-quality tires can extend tire life

Investing in quality tires and wheels can significantly reduce long-term costs and improve overall performance.

Understanding these components is just the beginning. Proper maintenance and timely replacement of these parts are key to keeping your chassis in top condition. In the next section, we’ll explore best practices for maintaining and inspecting these critical components to ensure optimal performance and longevity.

How to Keep Your Container Chassis in Top Shape

The Power of Regular Inspections

Regular inspections form the first line of defense against unexpected failures. The Federal Motor Carrier Safety Administration (FMCSA) requires commercial motor vehicles to be inspected at least once every 12 months. These inspections should cover:

- Tire condition and pressure

- Brake system functionality

- Lights and reflectors

- Suspension components

- Frame integrity

Small issues should not be overlooked. A minor problem today can lead to a major breakdown tomorrow.

Tackling Common Wear and Tear

Container chassis face constant stress from heavy loads and varied road conditions. Some of the most frequent issues include:

- Brake wear: Brake shoes and drums typically need replacement every 200,000 to 300,000 miles (depending on usage).

- Tire wear: Uneven tire wear can indicate alignment issues. Rotate tires every 50,000 miles to ensure even wear.

- Electrical failures: Corrosion on connections is a common culprit. Clean and protect electrical connections regularly.

- Suspension wear: Look for signs of sagging or uneven ride height, which can indicate worn springs or air bags.

Proactive Maintenance Strategies

Preventive maintenance costs less than reactive repairs. Here are some strategies to keep your chassis running smoothly:

- Lubricate moving parts regularly, especially fifth wheels and landing gear.

- Check and adjust brake systems every 25,000 miles or as recommended by the manufacturer.

- Inspect and tighten all bolts and fasteners quarterly.

- Clean the chassis thoroughly after exposure to corrosive environments, such as salt water or de-icing chemicals.

The Value of Quality Replacement Parts

Quality matters when it comes to replacement parts. Cheap, low-quality parts might save money upfront but often lead to more frequent replacements and potential safety issues. Investing in high-quality parts pays off in the long run.

Your chassis is only as strong as its weakest component. Don’t compromise on quality when it comes to replacement parts. The safety of your cargo and drivers depends on it.

Now that we’ve covered maintenance best practices, let’s explore how to choose the right chassis parts for your specific needs in the next section.

How to Select the Right Chassis Parts

Balancing Quality and Cost

Selecting the right parts for your container chassis impacts safety, efficiency, and cost-effectiveness. The decision process involves key considerations that affect your bottom line and operational performance.

It’s tempting to choose the cheapest option available. However, this approach often increases maintenance costs and potential safety risks. Focus on the total cost of ownership instead. High-quality brake shoes might cost more upfront but can offer longer-lasting performance, potentially resulting in lower overall expenses and reduced downtime for replacements.

OEM vs. Aftermarket: Making the Right Choice

Original Equipment Manufacturer (OEM) parts are designed specifically for your chassis model, ensuring perfect fit and optimal performance. They often come with a premium price tag. Aftermarket parts can offer significant cost savings – sometimes up to 50% less than OEM parts – while still meeting industry standards.

Evaluate each component individually. For critical safety components like brake systems, OEM parts are often the wisest choice. For less critical components, high-quality aftermarket parts from reputable manufacturers can provide excellent value without compromising performance.

Ensuring Compatibility and Compliance

Compatibility is non-negotiable when selecting chassis parts. Each part must fit perfectly and work seamlessly with existing components. Moreover, all parts must comply with industry standards and regulations. The American Trucking Associations’ Technology & Maintenance Council (TMC) provides recommended practices for various chassis components. Adherence to these guidelines ensures that your parts meet industry benchmarks for safety and performance.

Leveraging Technology for Better Choices

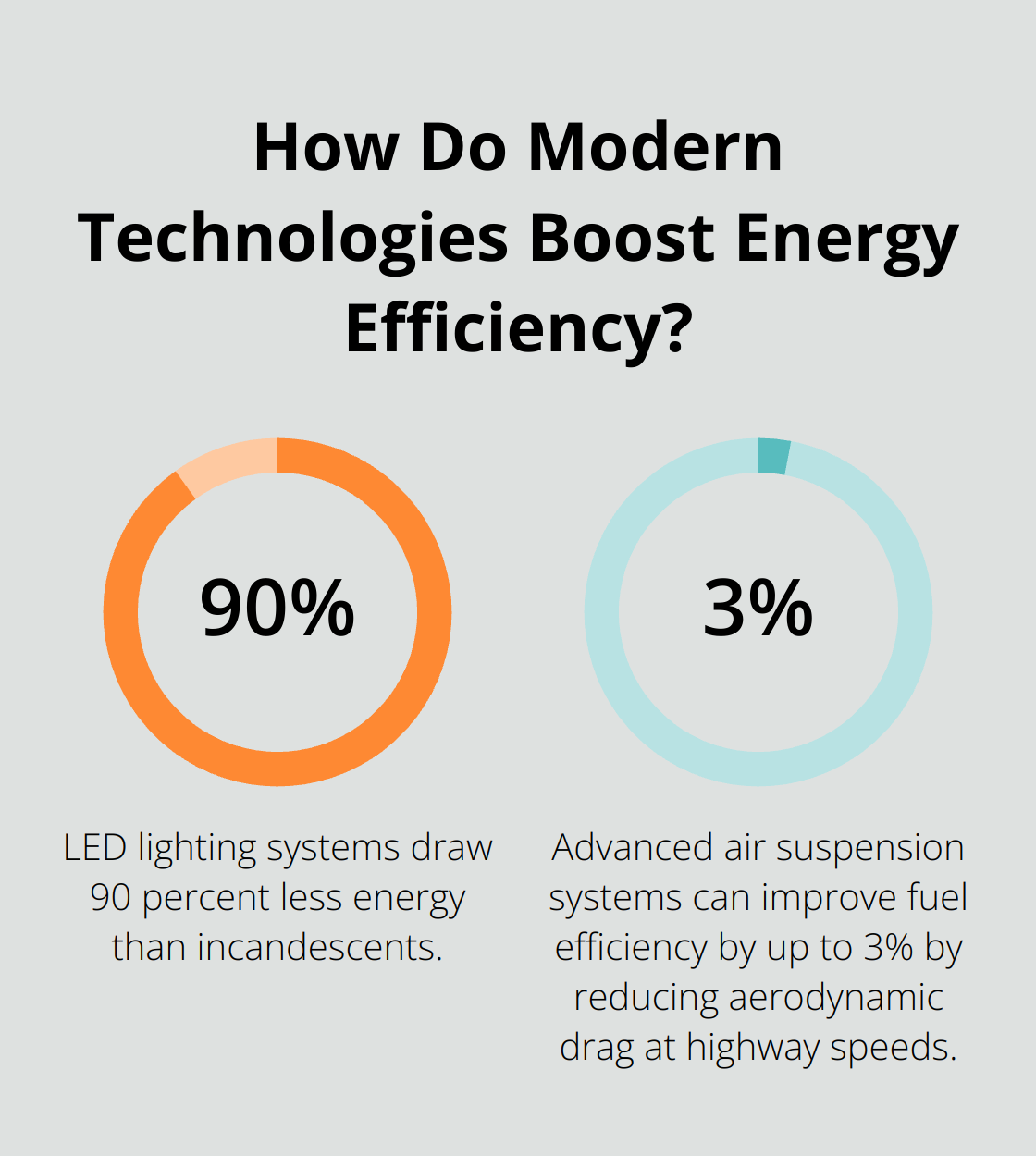

Modern chassis parts often incorporate advanced technologies that can enhance performance and reduce long-term costs. LED lighting systems draw roughly 90 percent less energy than incandescents and last significantly longer. Advanced air suspension systems can improve fuel efficiency by up to 3% by reducing aerodynamic drag at highway speeds.

When evaluating new technologies, consider not just the upfront cost but also the potential savings in fuel, maintenance, and operational efficiency. A slightly higher investment in advanced parts can lead to substantial savings over the life of the chassis.

Choosing a Reliable Supplier

The choice of supplier is as important as the choice of parts. Look for suppliers with a proven track record of quality and reliability. Delta Mark stands out as a top choice in the industry, offering a comprehensive range of high-quality container parts and accessories since 2001. Their expertise in intermodal container transport solutions makes them a trusted partner for reliable and efficient container solutions.

Final Thoughts

This guide explored essential container chassis parts names and their functions, emphasizing the importance of regular maintenance and quality components. We discussed key factors in selecting the right parts, balancing cost with performance, and the impact of technological advancements on chassis design. The transportation industry can expect future innovations in lightweight materials, telematics, and predictive maintenance systems, all contributing to improved safety and efficiency.

Delta Mark offers a wide range of high-quality container parts and accessories for those seeking reliable solutions. With over 20 years of experience, Delta Mark has established itself as a trusted partner in the container industry. Their expertise in intermodal container transport solutions makes them a go-to choice for many businesses.

Understanding container chassis components and maintaining them properly will ensure smooth operations in the global supply chain. As technology evolves, staying informed about industry advancements will help optimize chassis performance and longevity. Prioritizing quality parts and regular maintenance will contribute to safer and more efficient container transportation.