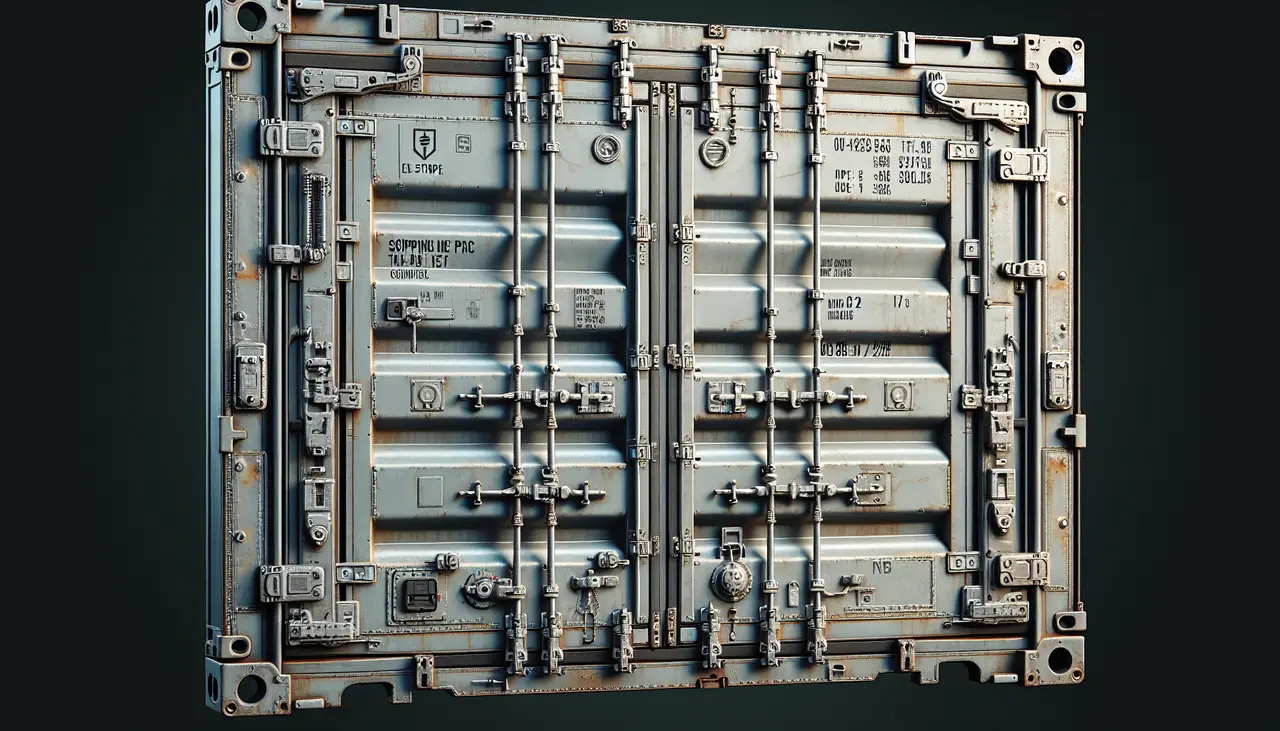

Introduction to Shipping Container Door Seals

Shipping container door seals are all about keeping what’s inside dry and safe, no matter the weather outside. Think of these seals as the unsung heroes of the shipping world. They’re strips of rubber or another durable material that line the edges of container doors. When doors are closed, these seals press tight against the container, blocking out water, dust, and pests. It’s like giving your container a superpower against the elements. There are different types of seals for containers, but they all have one job: to keep the bad stuff out while protecting the good stuff inside. Whether dealing with blazing sun, pouring rain, or relentless snow, a solid door seal makes all the difference. Remember, a broken or worn-out seal is as good as no seal. So, checking them regularly and replacing when needed is key to maintaining your container’s integrity.

The Importance of Weatherstripping in Shipping Containers

Weatherstripping in shipping containers is crucial; it’s what stands between your goods and the wild moods of Mother Nature. Think of weatherstripping as a superhero shield for your container. Without it, water, dust, and even pests can sneak into your container, wreaking havoc on your items. Weatherstripping ensures that your container is sealed tight, no matter if it’s blazing hot or freezing cold outside. This is essential not only for protecting the items inside but also for maintaining the container’s integrity over time. A container without good seals can get rusty or damaged quicker, meaning more headaches and expenses down the line. So, investing in quality weatherstripping? It’s a no-brainer if you want to keep your goods safe and your container in top shape for the long haul.

Types of Door Seals Used in Shipping Containers

Shipping containers need to be tough. They face the brunt of the sea, the sun, and everything in between. That’s where door seals play a hero role, keeping what’s inside safe and dry. These seals are not all the same, though. There are a few different types you’ll find on shipping containers. Brush seals are like the thick hair of a brush, stopping water and dust. Great for keeping things dry without making it hard to open the door. Rubber gasket seals are the classic. They form a tight seal all around the door edges, perfect for blocking out water completely. But they can wear out, so keep an eye on them. PVC seals are the tough guys. They’re strong against weather and wear and tear, making them a smart pick for long-term use. Each type has its place. The right one for a container depends on what you’re keeping inside and where it’s headed.

How Weatherstripping Protects Your Cargo

Weatherstripping is your shipping container’s first defense against the elements. Think of it as a tight shield that blocks rain, dirt, and pests from sneaking into your cargo. It’s all about keeping your items safe and dry, whatever the weather throws at them. Installed around the door edges, weatherstripping is a simple yet effective way to enhance the container’s seal. This is crucial, especially when your goods travel through different climates or sit in storage. Without proper sealing, moisture could sneak in, leading to mold or damage. It’s an affordable fix that makes a big difference in protecting your cargo.

Step-by-Step Guide to Inspecting Shipping Container Seals

First up, grab a flashlight. You’re going to need it to see all the nooks and crannies. Start at the top of the door and work your way down. You’re looking for any signs of damage like cracks or splits in the seal. These are your container’s armor against water and pests. If light can get through, water can too. Next, press along the seal with your finger. You’re testing for brittleness or soft spots. A good seal feels firm but not rock-hard. If bits crumble or it feels spongy, it’s time to replace. Check the corners closely. They’re the prime spots for wear and tear. Lastly, don’t forget the door hinges and locking mechanism. Rust or damage here can mean your container isn’t sealing tight. A simple inspection twice a year saves you from finding big surprises later on.

Easy Installation Tips for Shipping Container Door Seals

Installing new door seals on your shipping container is a straightforward task you can manage without professional help. Start by choosing a clear, dry day, as moisture can affect the adhesion of some seals. Here’s a quick guide to get you through the installation:

- Clean the area. Before you do anything else, make sure the door frame is free of dirt and rust. A wire brush and some cleaning solvent can do the trick. This ensures a smooth surface for the new seal to adhere to.

- Remove the old seal. Gently pry off the old seal. If it’s stubborn, a flathead screwdriver can help, but be careful not to damage the door frame.

- Measure twice, cut once. Before cutting your new seal to length, double-check your measurements. It’s better to cut the seal a bit longer and trim as needed than to end up short.

- Apply adhesive, if needed. Some seals come with adhesive backs, while others require a separate adhesive. If you’re using the latter, apply a thin, even layer to both the seal and the door frame, then wait a few minutes for it to become tacky.

- Press the seal into place. Starting at one end, firmly press the seal onto the door frame, working your way along to ensure no gaps or bubbles. For adhesive-backed seals, apply pressure across the entire length to secure it.

- Check the fit. Close the door to make sure the seal fits snugly without preventing the door from sealing properly. If the door won’t close, you may need to adjust the position of the seal.

Remember, a good seal keeps out moisture, pests, and dust, protecting the contents of your shipping container. Taking the time to do it right will save you headaches down the road.

Maintenance and Replacement: Keeping Your Seals Effective

To keep your shipping container weatherproof and secure, regular checks on door seals are a must. These seals, making sure water, dust, and pests stay out, can wear down or get damaged. You spot a problem? Fix it fast. For light damage, a simple clean might do. Dirt buildup can break a seal’s effectiveness, so a thorough scrub can bring it back. If the damage’s beyond a simple fix, replacement is your next step. Choose quality replacement seals that match your container’s specs. Don’t skimp on quality here; a good seal keeps your container’s contents safe from the elements. Regular maintenance, like checking seals every few months and after harsh weather, prevents bigger headaches down the road. In short, keep those seals in check, replace when needed, and choose quality replacements. This effort keeps your shipping container tight and right.

Common Problems and Solutions with Shipping Container Seals

Shipping container seals keep your cargo dry and secure. But sometimes, they fail. Here’s the lowdown on common problems and how to fix them. Leaks happen when seals age or get damaged. If you spot moisture inside, check the door seals for cracks or gaps. A simple replacement might be all you need. Misalignment is another headache. It can stop doors from closing properly, making it easy for water and pests to get in. To fix it, you might need to adjust the door hinges or replace the seals if they’re too worn. Wear and Tear is unavoidable. Over time, seals degrade from exposure to the elements. Regularly inspect them and replace as necessary to keep your container tight. Lastly, Improper Seals can be a pain. Not all seals fit all containers. If you’ve got the wrong type, they won’t do their job. Make sure you get seals designed for your specific container type. In summary, keep an eye on your seals, replace them when needed, and always go for quality replacements. A little maintenance goes a long way in protecting your cargo.

Innovative Weatherstripping Materials and Technologies

The world of shipping container door seals and weatherstripping is evolving fast. New materials and technologies are coming up to keep goods dry and safe during transport. First off, silicone is a game changer. It’s flexible, withstands extreme temperatures, and lasts longer than most materials. Then there’s TPV (thermoplastic vulcanizate), combining plastic’s durability with rubber’s elasticity, making it perfect for tough weather conditions. Another standout is PVC (Polyvinyl Chloride), known for its resistance to sunlight, chemicals, and fire, not forgetting its affordability. On the tech side, self-healing materials are the future. Imagine a seal that fixes its own cuts and tears! Plus, smart weatherstripping with integrated sensors can now alert you to leaks or seal breaches in real-time. These advancements aren’t just about protection; they’re about peace of mind and saving money on damages and repairs in the long run.

Conclusion: Ensuring the Longevity of Your Shipping Containers

To keep your shipping containers in top shape for as long as possible, focus on their door seals and weatherstripping. These elements are crucial for protecting your goods from water damage, pests, and extreme temperatures. Remember, a small investment in high-quality door seals and weatherstripping now can save you from hefty repair or replacement costs down the line. Regularly check these parts for wear and tear and address any issues promptly. By taking these steps, you’re not just ensuring the longevity of your shipping containers but also safeguarding the valuable contents inside. Keep it simple: Look after your seals, and they’ll look after your cargo.