Shipping container door latches are critical components that ensure cargo security and protection. When these mechanisms fail, it can lead to costly delays and potential damage to goods.

At Delta Mark, we understand the importance of maintaining and repairing these vital parts. This guide will walk you through common issues, essential shipping container door latch parts, and step-by-step repair instructions to keep your containers secure and functional.

What Causes Shipping Container Door Latch Problems?

Shipping container door latches face numerous challenges that can compromise their functionality and security. Let’s explore the most common problems affecting door latches and their root causes.

Rust and Corrosion: The Silent Destroyers

The maritime environment is notoriously harsh on metal components. Salt water and humid conditions accelerate the formation of rust and corrosion on door latches. Rust and corrosion can target the locking mechanisms and hinges, ultimately impeding the smooth operation of the container’s doors. Regular inspections and immediate treatment of rust spots prevent extensive damage.

Misalignment: A Matter of Precision

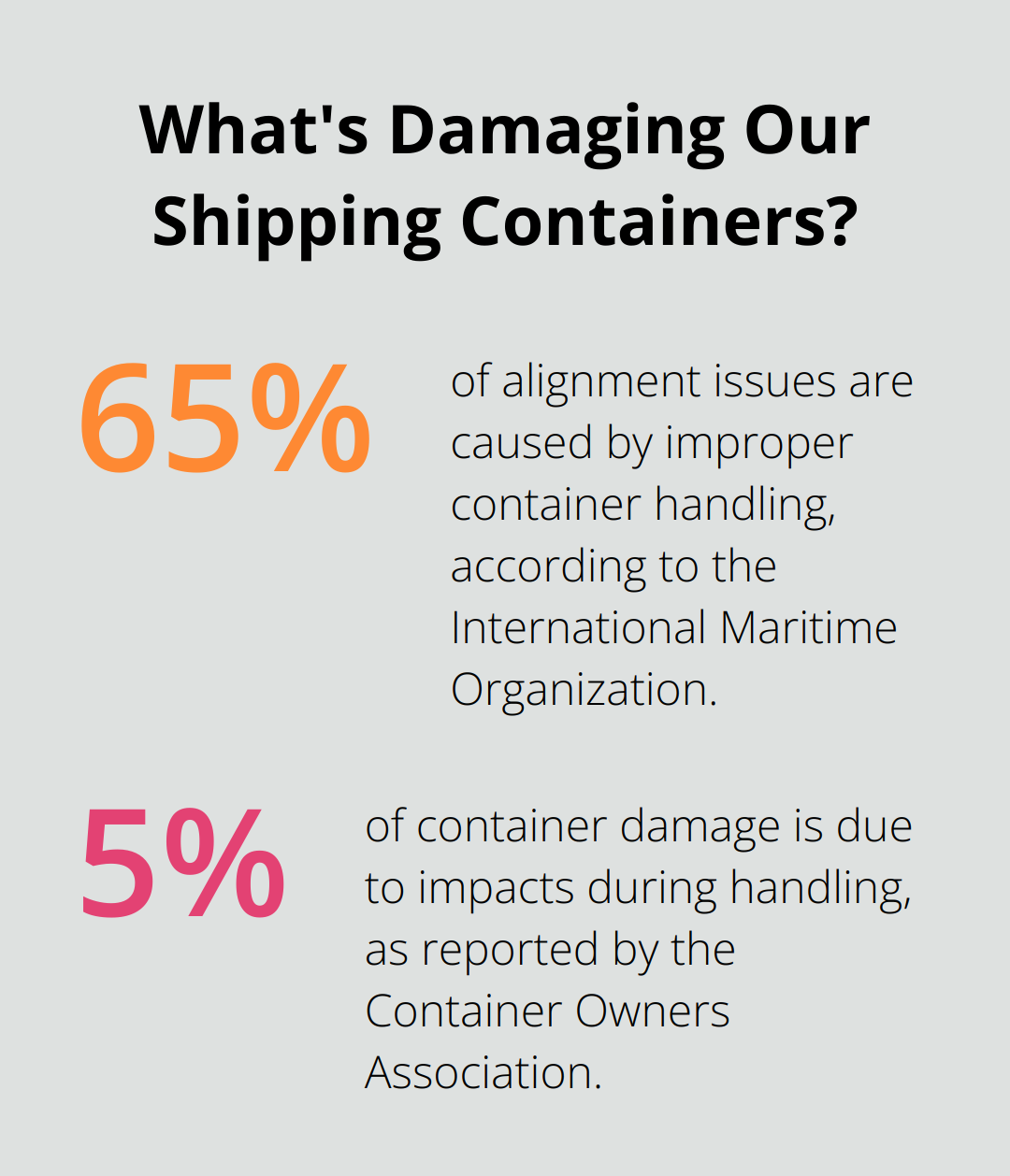

Frequent loading and unloading, coupled with the stress of long voyages, can lead to door misalignment. Even a slight shift can cause latches to jam or fail to close properly. The International Maritime Organization reports that improper container handling accounts for 65% of alignment issues. The use of specialized alignment tools during maintenance helps prevent this problem.

Wear and Tear: The Inevitable Challenge

Like any mechanical component, door latches wear out over time. Shipping containers are designed to take a lot of abuse and see a lot of use, and as a result, they can last for up to twenty-five years. However, factors like usage frequency and environmental conditions can significantly reduce this timeframe. A proactive replacement schedule for high-wear parts minimizes unexpected failures.

Impact Damage: Accidents Happen

Forklifts, cranes, and other handling equipment can accidentally damage door latches during loading or unloading operations. The Container Owners Association reports that approximately 5% of container damage is due to impacts during handling. Training personnel in proper container handling techniques and using protective barriers reduces the risk of such incidents.

Addressing these issues promptly is vital for maintaining the integrity of shipping containers. While some problems may seem minor at first, they can quickly escalate into major security risks or operational delays if left unchecked. Regular maintenance and timely repairs using high-quality parts (such as those provided by industry leaders like Delta Mark) are essential for keeping container door latches in optimal condition.

Now that we’ve identified the main causes of door latch problems, let’s move on to the essential parts needed for repairing these critical components.

Essential Parts for Container Door Latch Repairs

Repairing shipping container door latches requires specific components. This chapter identifies the key parts needed for effective repairs.

Door Handle Assemblies: Primary Interface

Door handle assemblies serve as the main point of interaction between operators and the container’s locking mechanism. These assemblies typically include:

- The handle

- Mounting plate

- Associated springs and bolts

Industry data shows that handle assemblies constitute about 30% of all door-related repairs. When replacing these components, it’s important to select parts that match the original specifications (ensuring proper fit and function).

Locking Rods and Cam Keepers: Load Security

Locking rods and cam keepers work in tandem to secure container doors. The rods extend vertically and engage with keepers at the top and bottom of the door frame. For replacements, corrosion-resistant materials like stainless steel or galvanized iron offer the best longevity.

Locking Gear Boxes: System Core

The locking gear box translates the door handle’s motion into the movement of the locking rods. This complex component is vital for the smooth operation of the entire locking system. Industry experts suggest replacing gear boxes every 5-7 years (depending on usage) to prevent unexpected failures.

Seals and Gaskets: Environmental Protection

High-quality seals and gaskets maintain a watertight and airtight container environment. Premium-grade rubber or silicone gaskets (rated for marine environments) can significantly reduce the risk of water damage.

Hinges and Bushings: Movement Facilitators

Hinges and bushings support the weight of container doors and enable their movement. These components can wear down over time, leading to misalignment issues. Annual inspections and prompt replacements at the first signs of wear help prevent more severe door problems.

Keeping these essential parts in stock and replacing them proactively can significantly reduce downtime and maintain fleet security and functionality. High-quality components from reputable suppliers ensure longer-lasting repairs and better overall container performance. Delta Mark, for instance, offers a wide range of these essential parts, making it a top choice for container operators looking for reliable replacements.

Now that we’ve covered the essential parts for container door latch repairs, let’s move on to the step-by-step guide for replacing these components.

How to Replace Door Latch Components

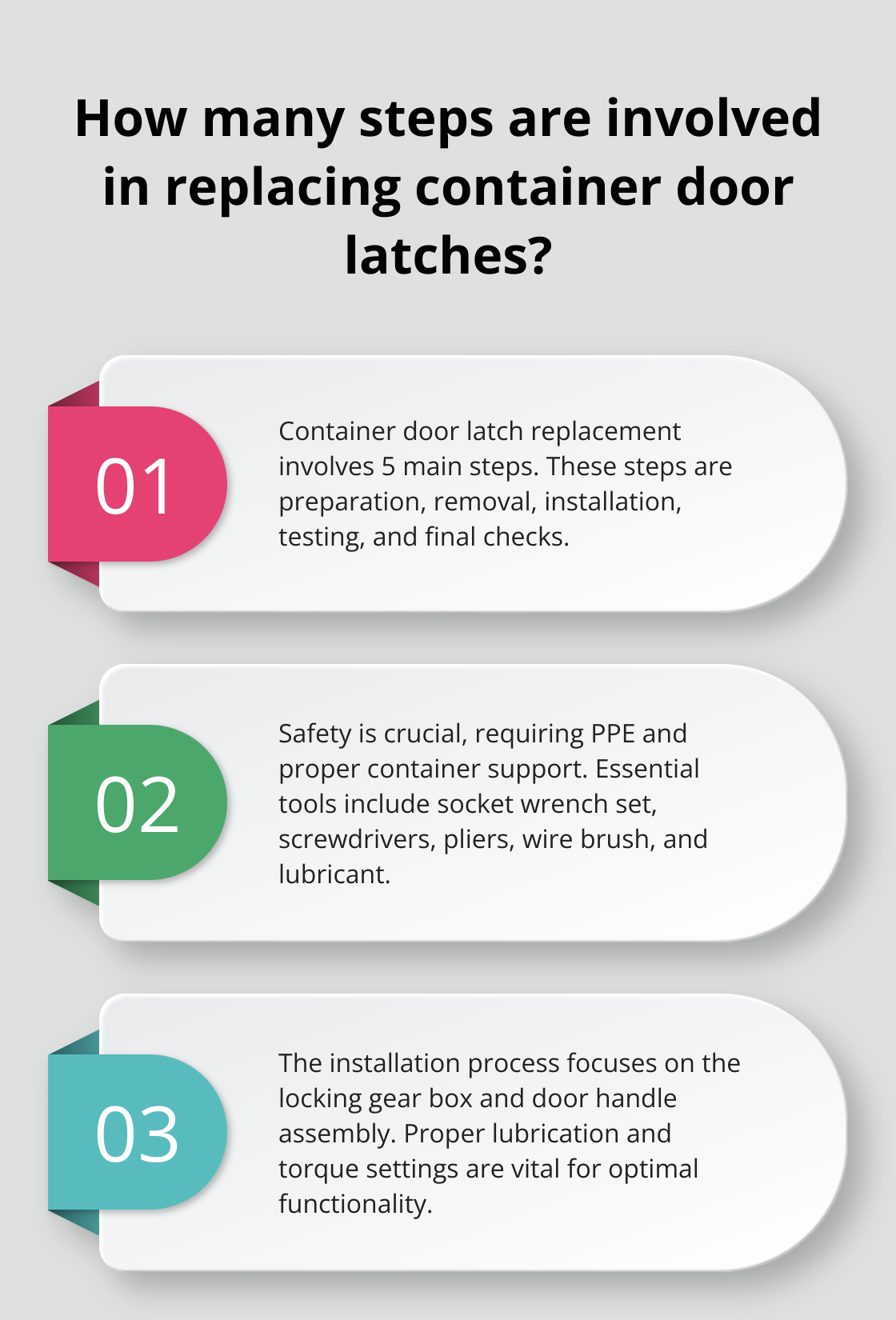

Preparation and Safety

Safety comes first when replacing shipping container door latch components. Put on appropriate personal protective equipment (PPE), including safety glasses, gloves, and steel-toed boots. Place the container on level ground and support it properly to prevent unexpected movement during repairs.

Collect all necessary tools before you start:

- Socket wrench set

- Screwdrivers (flathead and Phillips)

- Pliers

- Wire brush

- Lubricant (marine-grade)

- Cleaning solvent

- Replacement parts

Removal and Cleaning

Open the container doors fully and secure them in place. Remove the old or damaged latch components carefully, noting their positions and interactions with other parts. This methodical disassembly will facilitate easier reassembly.

Clean the door frame and surrounding areas thoroughly with a wire brush and cleaning solvent. Remove all rust, dirt, or debris that could interfere with the new components.

Installation Process

Start the installation with the locking gear box if it needs replacement. Lubricate all moving parts well before installation. When fitting new locking rods, adjust them to the correct length for proper engagement with the cam keepers.

Install the door handle assembly, aligning it correctly with the gear box. Tighten all bolts and screws to the manufacturer’s specified torque settings. Avoid over-tightening (which can lead to premature wear) or under-tightening (which may result in loose components and security risks).

Testing and Adjustment

Test the latch system thoroughly after installation. Open and close the doors multiple times to check for smooth operation and proper engagement of all components. Listen for unusual sounds that might indicate misalignment or improper installation.

Make necessary adjustments to ensure the doors close tightly and the locking mechanism engages fully. Focus on the alignment of the cam keepers with the locking rods. Even slight misalignment can compromise the container’s security.

Final Checks

Conduct a final inspection of all installed components. Look for any signs of stress or improper fit. Apply a weather-resistant lubricant to all moving parts to ensure long-term smooth operation.

Test the watertightness of the door seals with a light test. Close the doors and inspect from inside the container for any light penetration around the edges. If you see light, adjust the door seals or locking mechanism as needed.

While DIY repairs can save money, complex issues or repairs on specialized containers may require professional assistance. Companies like Delta Mark offer expert repair services and high-quality replacement parts, ensuring container doors meet industry standards for security and functionality.

Final Thoughts

Regular inspections and timely repairs of shipping container door latches prevent costly delays and security breaches. Operators extend container lifespans and maintain optimal functionality when they address issues promptly. The use of high-quality shipping container door latch parts improves durability, enhances security, and reduces long-term maintenance costs.

Quality components withstand harsh maritime conditions, resist corrosion, and provide reliable performance over extended periods. This investment ensures cargo safety and contributes to smoother operations with fewer unexpected breakdowns. Premium parts protect valuable cargo and support efficient logistics in global trade.

Delta Mark offers a comprehensive range of high-quality container parts and accessories for the shipping industry. Their expertise and products help keep containers in top condition (from essential door hardware to specialized reefer components). Operators who prioritize proper maintenance and partner with reputable suppliers ensure the longevity, security, and reliability of their shipping containers.